News & Technical Info

Three Stories Masonry Wall Capacity and Behavior Second Progress Report

by Fernando S. Fonseca, Ph.D., S.E. and Ernesto Fortes, Jeff Buxton, David Ochoa, and Kyle Chavez, Graduate Students

Summary

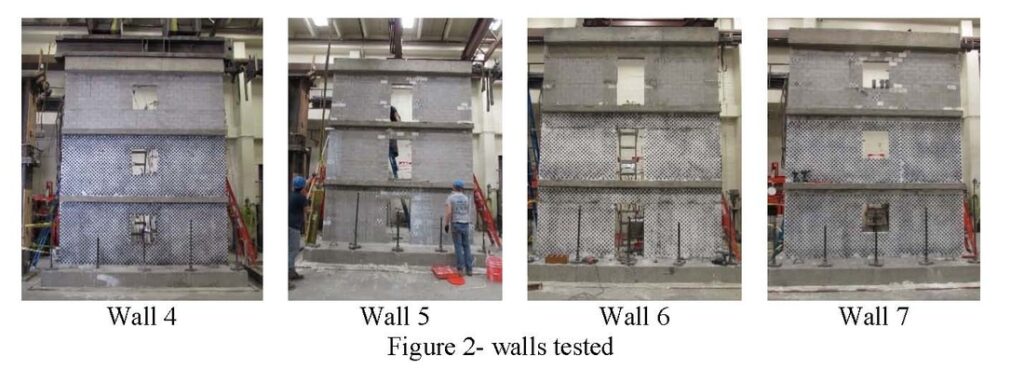

Lateral load testing has been performed on four wall specimens (walls 4, 5, 6, and 7) with plans to test three more specimens in the near future. The testing was conducted to determine the shear strength and failure mode of the walls.

Construction

Construction of each wall began with casting a reinforced concrete footing measuring approximately 305 mm × 1219 mm x 4064 mm as shown in Figure 1.

The specimens are half-scale and the designs represent a three-story shear wall. Wall 4 has windows in the center of the wall as shown in Figure 2. Walls 5 and 6 have doors but wall 5 has a masonry beam above the doors while wall 6 has a reinforcement concrete T-beam.

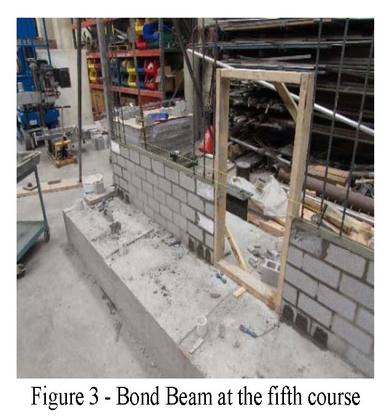

Researchers made a slight change on the design of the walls (from the previous walls) in an attempt to improve their behavior. A bond beam, as shown in Figure 3, has been added on the fifth course of every wall.

Wall Testing

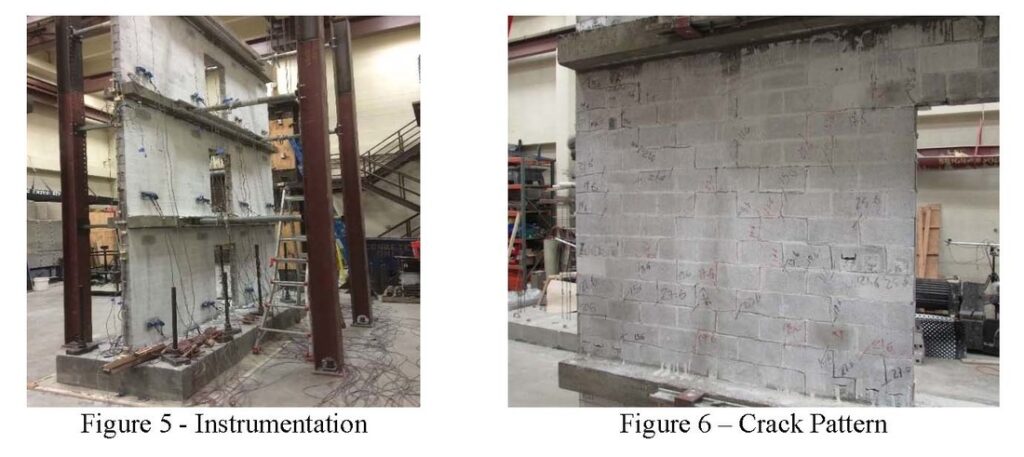

Walls were tested using a custom reaction/testing frame that allows the MTS actuator to push and pull the walls cyclically at increasing loads and/or displacements as shown in Figure 4. The walls were instrumented with LVDTs, string pots, and strain gauges as shown in Figure 5. After each push or pull, cracks were documented to track their development and propagation as shown in Figure 6.

Failure Modes

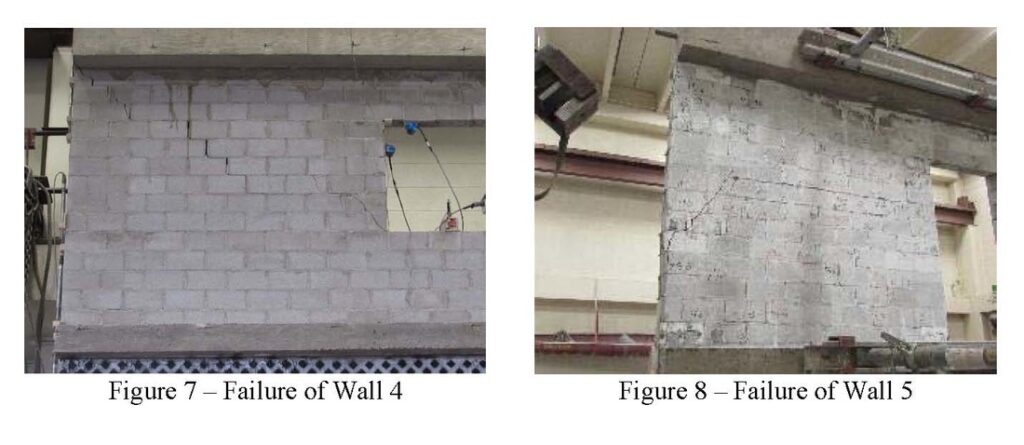

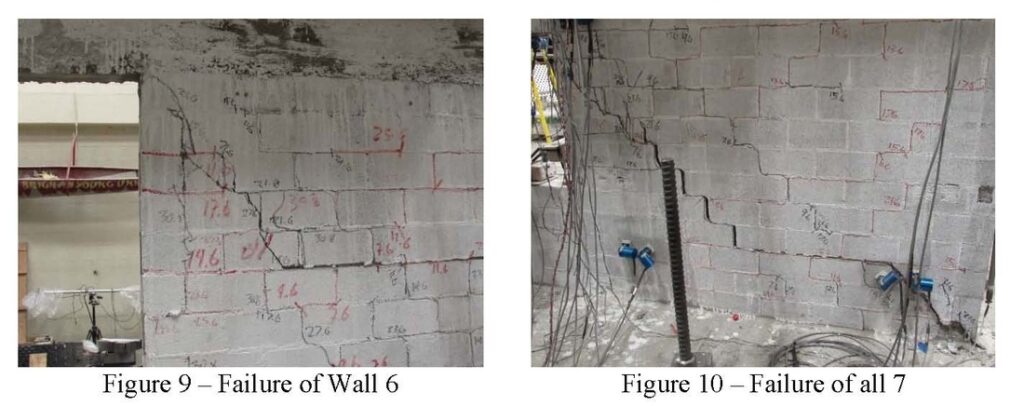

All walls experienced a shear failure. Wall 4 (with windows) failed in the third story as shown in Figure7. Wall 5 (with doors and a masonry beam above the doors) also failed in the third story as shown in Figure 8. Wall 6 (with doors and a reinforcement concrete T- beam above the doors) failed in the third story as well as shown in Figure 9. Wall 7 (with windows) in the first story as shown in Figure 10.

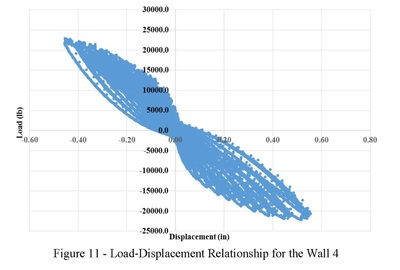

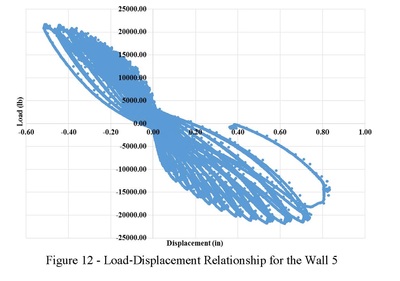

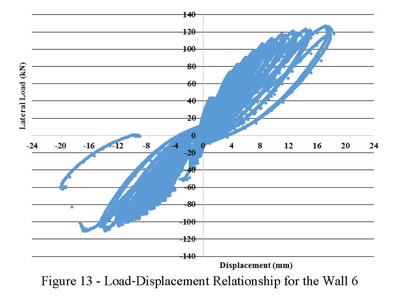

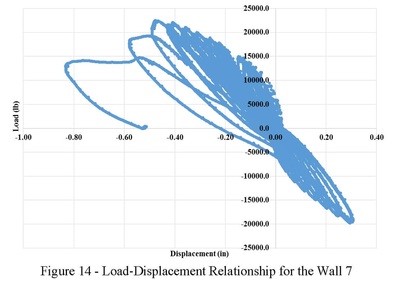

Load-Displacement Relationships Figure 11 to Figure 14 shows the load‐displacement relationship, as measured at the top of the wall, for walls 4, 5, 6, 7, respectively.

Three more walls will be constructed and tested. Wall 8 is being prepared to be tested in the 3rd week of January. Wall 9 is completed and will be tested in the last week of January. Wall 10 is almost completed and will be tested in the second week of February.

Refractory mortar for masonry fireplace and chimney construction

By Jim Buckley, Bob Rucker

In recent years, we have seen vast changes regarding masons’ preferred choices of mortar for firebrick (fireplace) and clay flue liner (chimney) installations. Jobsite prepared mortars that may have included fireclay and Portland cement are now out of favor. Factory prepared refractory mortar is now the most widely accepted standard.

Refractory mortars have become easier to use, safer, are more readily available, and meet all of the local and national building codes. Masons who resisted them at first, now accept them as a better, safer masonry product, offering their customers a higher quality installation. No more guesswork regarding homespun mortar formulations, liability issues, or concerns regarding code compliance. And, without getting into all of the detail about the fireclay mixes breaking down and losing strength as they pass through the temperature range of 600 to 800 degrees, they simply don’t take the heat like refractory mortars do, nor do they have the strength or acid resistance.

While our building codes may have been a bit confusing or inconsistent in previous decades, that is no longer the case. The International Code Council (ICC), the International Residential Code (IRC) and the National Fire Protection Association (NFPA-211) now all require refractory mortar tested to American Society for Testing Materials, ASTM C-199, medium duty. Also called out in these codes are the high-temperature resistant manufacturing standards for firebrick (ASTM C-27 & C-1261) and for clay flue lining (ASTM C-315). It does make sense that the mortars used for installation of firebrick and clay flues should be manufactured to a high-temperature resistant standard as well. After all, what part of residential construction should have more attention to fire safety than that part in which we are going to intentionally build a fire?

There are basically two kinds of refractory mortar conforming to ASTMC-199 and permitted by code. Non-water soluble refractory mortar (sometimes called hydraulic setting) is a dry blend, requiring only cold water to be added, usually ships in a bag, and sets up or cures much like a regular mortar mix. The second type is a premixed version. It comes in a pail and is about the consistency of drywall compound. It usually requires no additives, and with a little mixing is ready to use.

NON-WATER SOLUBLE REFRACTORY MORTAR

This type of refractory mortar is a blend of aggregates and binders that are not only high-temperature resistant, but also are acid resistant. This product is now the best all-around refractory mortar for fireplace and chimney construction. It is also the preferred choice for installation of the high-temperature resistant component parts for masonry bread ovens. It has the workability of a regular mortar mix, may have mortar color added to it, and is preferred if the joint thickness exceeds 1/8-inch. (By the way, always strike or finish smoothly the face of the joints, just like on a regular masonry wall, no matter the thickness of the joint.)

Non-water soluble refractory mortar is the only refractory mortar that should be used in outdoor applications. Premixed refractory mortars may wash out, even after drying. Due to the previously mentioned characteristics, non-water soluble product is the preferred choice for clay flue installations that may vent gas or oil appliances, or in any other instance in which moisture may be present within the clay flue. This is our overall refractory mortar of choice. It is used four to one versus other types of refractory mortar in residential construction.

PREMIXED REFACTORY MORTAR

Premixed refractory mortar is a blend of clays, aggregates, and has a liquid silicate as a binder. Some masons prefer it simply because it is premixed, nothing needs to be added, and with a simple quick stir it is ready to use. Since the firebrick can be laid in place very rapidly (as with a firebox with firebrick joints 1/16- to 1/8-inch thick, for example) installation is a little quicker. Ten seconds after setting the firebrick, it takes some effort to dislodge them, and the fast-drying of the mortar does not compromise its strength like with regular mortar.

We usually recommend building Rumford firebox walls straight up, but premixed mortar makes building even a curved or slant firebox a breeze, because you don’t have to form it or wait long for the mortar to set up. Premixed mortar can be a little messy to use, but remember, it is water soluble, so it cleans up easily with water.

You should butter a thin layer of refractory mortar on the firebrick that you are going to lay. Use a small margin trowel, because it fits in the bucket better than a pointed trowel. After applying a small amount on the firebrick, tap the firebrick in place so that the joint thickness is about 1/16-inch, and the excess mortar that oozes out from between the firebrick is removed with the margin trowel. Take your time and avoid the mess. The best thing is to lay a few firebricks, and then clean up the face of the firebrick with a sponge and clean water. The longer you wait to clean up the face of the firebrick, the harder it is to get all the particles saturated and removed.

In hot and dry climates we prefer the premixed refractory mortar, because it does not seem to dry out as quickly as do other mortar types. Pre-wetting the firebrick helps if ambient conditions are hot and dry, no matter which type of refractory mortar is used. Even though there are some things that we prefer about the premixed products, the non-water soluble hydraulic setting refractory mortar is our first choice for all applications. In colder and damper climates, there is no question we like it better.

QUESTIONS ANSWERED

Q: How long does the installation need to set after completion before building a fire?Bob: One overnight of drying is sufficient for any installation.

Q: Where else do you use refractory mortar on your Rumford installations?

Jim: I use refractory mortar for setting the firebrick and the throat and then for installing the smoke chamber as well as all of the clay flue lining.

Q: Where can people find all they need to know about a masonry fireplace, chimney, or bread oven?

Jim: Try www.rumford.com.

Q: Any new publications regarding masonry fireplace or chimney construction?

Bob: New York State Concrete Masonry Association, Tech Spec 3.5, online at www.nyscma.org.

Originally published in Masonry magazine.

ABOUT THE AUTHORS: Jim Buckley is CEO at Buckley Rumford Co.

Bob Rucker is president of CMS Industries, Inc.

Important Feedback Needed for MSJC

The Utah Masonry Council is represented on the MSJC by Dave Pierson, ARW Engineers in Salt Lake City. Dave has done an excellent job of representing the interests of the Utah Masonry Industry in national discussions regarding building codes and standards. He recently returned from MSJC meetings in Greenville, South Carolina and has requested some feedback from masons and suppliers in Utah. Please take a minute and respond to Dave’s questions in the adjacent column to the right.

Thanks for your assistance.

The Utah Masonry Council

Vertical rebar positioners Take the guesswork out of rebar placement

By Mike Ripley

Vertical rebar positioners aid the mason contractor in centering the bars in the core of the block.Vertical rebar positioners have been part of the masonry accessory package for many years. They add no structural value to the wall, but aid the mason contractor in centering the bars in the core of the block and also help to simplify the lapping process.

The most popular and economical positioners for vertical applications are the Figure 8 or S type and the O ring. They are installed perpendicular to the plane of the block crossing the core with the wire loops centered. Positioners are set in the mortar of the bed joint for stability and vertical spacing is about every four feet.

Placement tolerances for single rebar applications are listed in Specification for Masonry Structures (TMS 602-08/ACI 530.1-08/ASCE 6-08) under Part 3 – Execution 3.4 B.8. Working from the center point of the core you are allowed + ½ inch in the width or thickness of the wall and 2 inches along the length of the wall. This leaves you a space in the core center of 1 inch wide by 4 inches long to be code compliant for vertical applications.

Some masons install bars manually (by sight) and others with the aid of positioners but all with the risk of not meeting code. While the use of rebar positioners greatly narrows the margin of error, they also move during installation due to sitting on top of the shelf of the CMU and moving when mortar or the next course is applied.

A new trend in vertical rebar positioners has emerged to solve the movement issue during installation. Core inserted positioners, which are designed to fit 1½-inch deep, cross the core diagonally and fit tightly in the corners of the core. The core positioners perfectly position the bars in the code compliance zone and allow no movement during installation. They also have an extended tail section (safety bend) so if installed incorrectly (out of plane), the tail will extend outside the wall alerting the mason to turn it in the opposite position.

Double vertical core positioners are also available but with a different design, spacing the loops or guides closer to the face shell of the CMU. To complete the family there is a bond beam positioner that positions bars in the lower one-third of the unit and ½-inch off the inside face shell.

Take the guesswork out of rebar placement by using the core inserted positioners.

Originally published in Masonry magazine.

ABOUT THE AUTHOR

Mike Ripley is National Sales Manager for Wire-Bond.